Christmas is the busiest time of year for UK eCommerce. Order volumes can easily triple compared with a standard month, carriers reach the breaking point, and returns spike as soon as January arrives. For brands trying to manage fulfilment in-house, the season often exposes every weak link in their operation.

With online sales already climbing in 2025 and shoppers starting earlier than ever, now is the time to plan. Here’s what UK retailers need to know to avoid peak season chaos, and how partnering with a 3PL like Cloud Fulfilment can make all the difference.

Why Christmas is Different

Peak season isn’t just “more of the same.” It creates new challenges:

- Concentrated demand surges: Black Friday and Cyber Week can push daily order volumes to three to five times the norm.

- Carrier pressure: Major couriers apply surcharges and restrict extra capacity by November. Even large retailers struggle to secure more space once allocations are set.

- Returns overload: Fashion brands in particular can face 30–40% returns on Christmas sales, which hit all at once in January.

- Weather unpredictability: UK storms and flooding disrupt road and rail each December, leading to delivery backlogs and customer frustration.

These issues can quickly overwhelm businesses that only prepare for “business as usual.”

Inventory and Forecasting: Getting It Right

Running out of stock during December means missed sales you’ll never recover. Holding too much ties up cash and storage space. The answer is scenario planning:

- Base plan: Reflects last year’s sales and this year’s marketing.

- High plan: Adds uplift for promotions or wider product ranges.

- Viral plan: Accounts for one or two SKUs suddenly surging in popularity.

Brands that plan only for the base case often scramble when demand spikes. Building in flexible storage and a buffer of extra stock reduces this risk.

Cut-Off Dates and Delivery Promises

Carrier “last posting” dates are useful, but they shouldn’t be treated as promises. With delays common in December, brands need to build in 2–4 days of margin for order processing, weather disruption, and courier backlogs.

The best 3PLs adjust cut-off dates dynamically, monitoring carrier performance and re-routing orders when certain networks slow down. That agility can preserve sales while still meeting customer expectations.

The January Returns Wave

For many retailers, the challenge doesn’t stop when Christmas ends. January brings a flood of returns, including unwanted gifts to duplicates and size exchanges. Processing these takes warehouse space, cash flow, and labour at a time when teams are already stretched.

A structured returns process is vital:

- Clear returns windows and policies set before Christmas.

- Pre-booked returns capacity with your fulfilment partner.

- Quick inspection and restock to recover revenue from returned stock.

How a 3PL Like Cloud Fulfilment Helps

Outsourcing peak operations to a 3PL is not just about extra storage or faster picking. It’s about resilience. At Cloud Fulfilment, we support UK eCommerce brands with:

- Scalable capacity: Seasonal staff, extended operating hours, and flexible warehouse layouts keep orders flowing when demand triples.

- Multi-carrier access: As part of the Parcel Monkey Group, we have direct access to a broad courier network, so your parcels are not locked into one provider.

- Real-time visibility: Our order fulfilment software integrates with your sales channels, giving you accurate order tracking, live inventory data, and control even during peak.

- Returns management: We handle inspections, reprocessing, and restocking, so January doesn’t become a bottleneck.

This combination means you can maintain service quality while focusing on growth and customer experience.

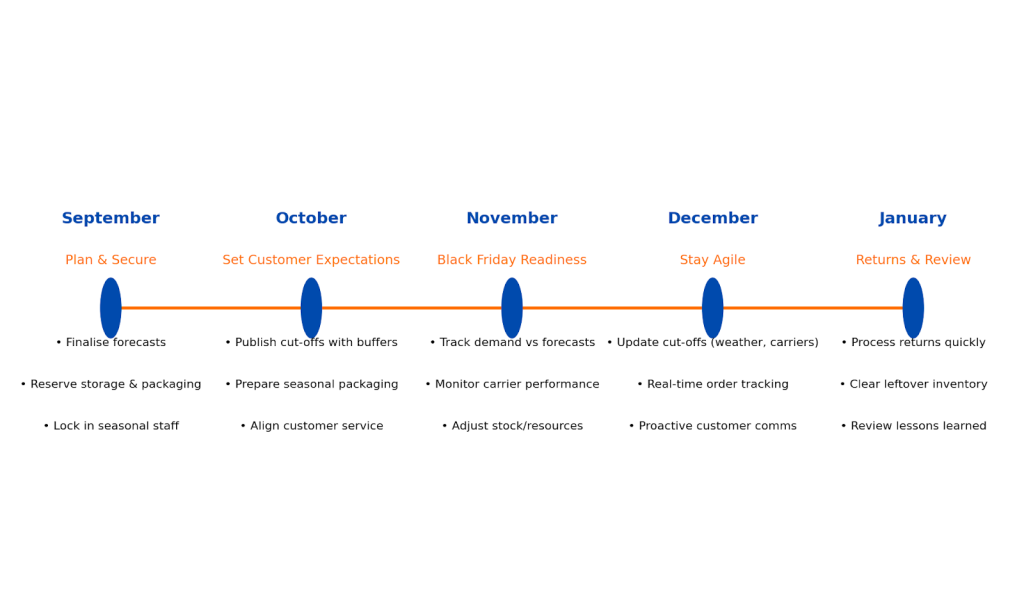

A Smarter Christmas Timeline

Peak success depends on starting early. A simplified preparation schedule looks like this:

- September: Finalise forecasts, secure overflow storage, and confirm packaging orders.

- October: Publish delivery cut-offs with safety buffers, prepare seasonal packaging, and set customer service processes.

- November: Monitor Black Friday demand closely, adjust forecasts, and confirm carrier performance.

- December: Stay agile with cut-offs, weather monitoring, and real-time order tracking.

- January: Process returns quickly, clear excess inventory, and review lessons for the year ahead.

The Christmas peak season will always stretch operations. But the brands that succeed are the ones that treat it as a project, with forecasts, buffers, and the right partners in place.

Cloud Fulfilment delivers the scalable capacity, technology, and multi-carrier flexibility UK eCommerce brands need to thrive during peak season. Instead of firefighting through December, you can focus on delighting customers and maximising sales.

Start preparing now. Your Christmas performance depends on it.